US Patent 9,592,542 B2

Minimize Downtime

Crude oil is notorious for developing sludge on the floor of the storage tank. The tank has to be taken offline and cleaned, which is hazardous, expensive, time-consuming, and requires sludge disposal.

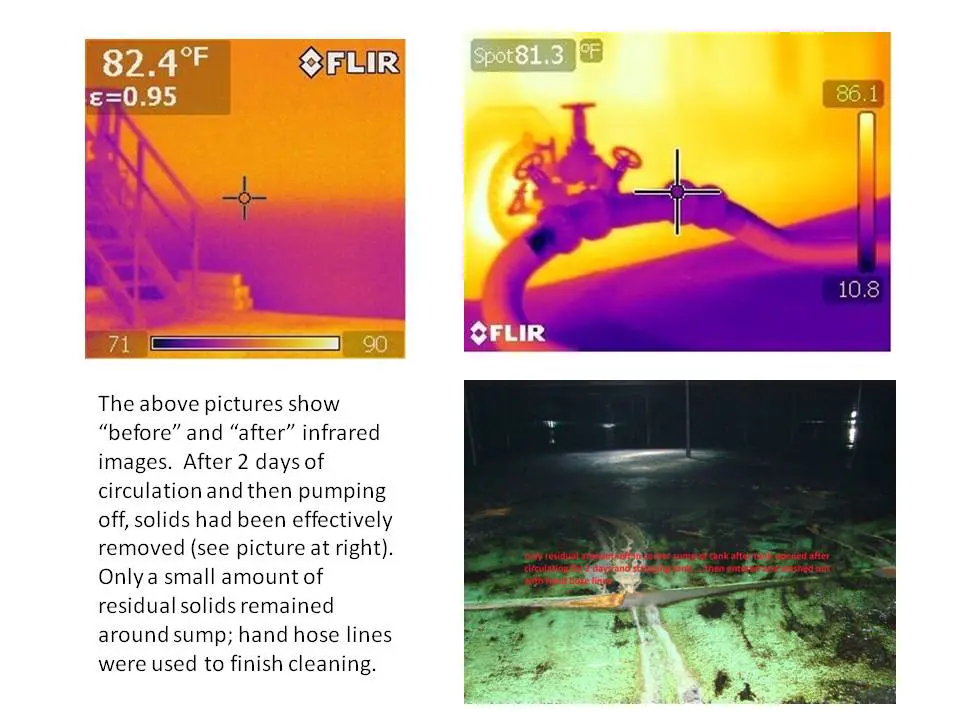

The Twister helps minimize the downtime needed for offline cleaning and/or tank entry prior to tank inspection and service intervals. The Twister works by directing a jet or plume of crude oil across the bottom of the tank, which dissolves and resuspends accumulated sludge. The Twister is fitted on a manway and replaces the existing manway cover, and requires no electrical or other power source other than a feed pump. This system allows the use of oil from the tank itself or a fluid from an outside supply source, such as cutter stock, to clean the tank.

It’s the permanent, easy to use, cost-effective solutio for storage tank cleaning!

Photo Gallery

FAQs

We would be happy to provide quotes on pumps, strainers, hose, etc., depending on your needs.

The Twister is a Submerged Jet Mixer, and shoots its discharge stream below the surface of the product, so you will be unable to see anything. However, when used for a water wash after desludging, a temporary bank of lights with a camera can be mounted as a separate accessory above the Twister.

Yes, via air actuation. However, we find that most clients prefer the simple manual operation, as typical circulation periods are 48 hours or less.

The Twister is designed to be almost maintenance-free for permanent installations. We do recommend activating the Twister handle to rotate the swivel on a quarterly basis, and using the 3” port to keep the area around the nozzle clear of solids buildup.

In many cases, frequent activation of the Twister can enable “Online Tank Cleaning”, so that the solids don’t have to be removed from the system because they have not accumulated to a level that will cause operational problems downstream. In cases where the resuspended solids can cause issues, it is prudent to have some type of material recovery system that can separate the solids and liquids, and the oil and water, so that all hydrocarbon value can be recovered and waste can be minimized. This system could be a 2- or 3-phase centrifuge.

Waterline offers a version of the Twister that can be inserted into a tank through an 18” fully open gate valve that a third party has hot-tapped onto the manway. We call this our “Hot Rod” Twister, and invite you to contact us for more details.

That depends on the solids settling characteristic of the product….in some crudes, Twisters may need to be activated every other week to prevent BS&W buildup from causing operational problems downstream. In other cases, a client may choose to activate every two years, with the express intention of removing any bad actors from the system, through perhaps a 3-phase centrifuge. And in other cases, a 10-year activation or more may be adequate.

Waterline builds two basic designs of the Twister. The first, designed for a permanent installation, has a 3” port intended to provide a means to keep the area around the swivel mechanism clear of solids buildup, by allowing either cutter to be introduced or a vacuum source to be applied, or both. For a temporary installation for tank cleaning, this feature is not relevant. So our second basic design has a 6” port in case suction needs to be taken through the manway and circulated through the pump and back into the Twister discharge. In that case, care must be taken to avoid cavitation on a short circuit.

Yes. This technique is used to lower LEL levels in the tank after desludging. Care must be taken to avoid static risk in a high LEL environment, so rates are often limited to <235 GPM (53 m3/hr)

The Twister provides an ideal delivery system for chemicals – both an entry point for the chemicals as well as the ability to achieve the intimate mixing and good surface contact needed to distribute the chemical effectively.

To help break up and resuspend the solids, it helps to have heat as well as a diluent. A typical temperature might be 140°F (60 °C), but depends on the flash point of the diluent. The diluent might be the product itself, or could be a compatible cutter stock such as diesel, VGO, LCO, etc. Often, a lab blend determines an effective level, but cutter-to-sludge ratios of 1:1 to 4:1 are common.

Absolutely! We believe the real value of the Twister is unlocked when Twisters are permanently installed on a tank, allowing “Online Tank Cleaning”…allowing the tank to remain in service….and not just a conventional offline tank cleaning. The Twister is a unique technology that provides a proactive ability to manage the sludge problem, with the tank in service….not waiting until after the solids have become out of control, and requiring a reactive technology (vacuum trucks, dozers, robots, chemicals, manway cannons, etc). Provisions are built into Twisters intended for permanent installation to ensure no build up of solids around the swivel mechanism and to provide fail-safe protection against any leaks.

A specific pump recommendation can be made for your application. In general, a self-priming high head centrifugal pump from 6” x 4” up to 10” x 8”, powered by 400 – 550 HP, and capable of 1000-2200 gpm (227-500 m3/hr) at 150 psi (10 bar) is adequate.

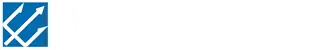

Again, it depends on the product, sludge level, heat, chemistry, and diluents, but often 48 hours of circulation is adequate to refluidize the solids.

Twisters have been built on manway covers as small as 20”, and as large as 36”.

The number of Twisters needed depends on the tank size and contents. A small tank (<60’ D, or 20 m) may only require 1 Twister. For most tanks, generally between 2 and 4 Twisters may be recommended, but the use of additional Twisters can reduce any “shadowing” behind tank internals. Being able to refluidize solids that can’t be directly reached by the jet stream of the Twister reduces the amount of time needed for detailed cleaning later. Often, the number of Twisters installed may be determined by the number of manways available. In some cases, as many as 7 Twisters have been installed on a 290’ D (88 m) tank in order to turn the tank around as quickly as possible.

Sludge level above the manway? Unable to remove the manway?

Try the Hot Rod Twister!

The “Hot Rod” Twister is designed for applications where the sludge level is above the manway, and thus prevents the manway cover from being removed for installation of a regular manway-mounted Twister. For details on effective use of the Twister, refer to our whitepaper “Using Twisters to Clean Black Oil Tanks – The Basic Approach”, available on request.

The Twister allows the operator complete manual control from outside the tank. Manually directing the flow through the Twister’s nozzle prevents “canyons” from being formed in the sludge/tank bottoms, as often results from fixed nozzles. The manual control also avoids the lock-up that can occur with automatic nozzles, besides being much more cost-effective.

The Twister may be left permanently on the tank without concern for the apparatus becoming inoperable due to sludge buildup. Regular use prevents sludge settling and water separation in the tank.

Installation Methods

Note: With both methods, boring the manway cover or sidewall is required.

Standard & Custom Models Available

The standard Twister is made of carbon steel and features a swivel joint, with our standard model using 150# flanges (rated for 265 psi at 200°F). Our standard swivel has nitrile seals and stainless steel bearings. Various materials of construction are possible, including stainless steel with more exotic swivel seals, as well as pressure ratings to 1000 psi and above. A number of lockable stops on the control handle allow the operator to govern the plume from the jet over a sweep of 120° degrees, in typically 15° increments. A typical tank might replace 2-7 manways with Twisters, depending on the diameter of the tank, ensuring minimal “dead spots” in the tank. The tank size and contents will help determine what pumping system is needed to provide adequate cutting and refluidization ability in the tank. Twisters only rotate in the horizontal plane, making it safe to use with any type of roof structure. Typically, the Twister will flange up to an 8″ inlet and be reduced to 2″ to 4″ discharge. The discharge from the Twister is a tight jet plume, often described as a “rifle shot” vs a “shotgun pattern” from other tank mixers.

Saving millions on tank cleaning, and allowing sludge prevention….not just removing

and disposing of sludge and other solids after they have become a problem….by enabling Online Tank Cleaning