The History of Triton Industries

In Greek mythology, Triton was a demigod of the sea, who could alter the fate of seaward travelers and change the face of continents by unleashing the incredible power of the sea at will.

Triton Industries took its name from the Greek mythological figure to present its innovative industrial strength vacuum system — and to help the most forward thinking customers recognize the possibility for changing the face of an industry dominated by high cost and inefficient systems.

Triton Industries took its name from the Greek mythological figure to present its innovative industrial strength vacuum system — and to help the most forward thinking customers recognize the possibility for changing the face of an industry dominated by high cost and inefficient systems.

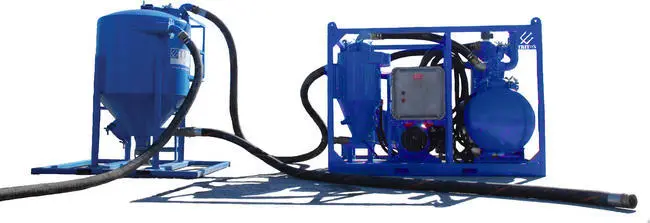

Triton’s concept is a simple one — to create a cost-effective industrial vacuum system, which is safe, compact, easy to operate, and powerful enough to effectively perform in the most demanding industrial settings, particularly petrochemical, marine barge and offshore environments.

1997 – The First Triton Vacuum System

1997 – The First Triton Vacuum System

In August of 1997 Michael H. James incorporated more than 20 years of his experience in industrial plants and pioneered the first Triton vacuum system. Today they are used by customers all around the globe in a wide variety of applications.

Triton’s vacuum systems use motors and pumps as powerful as any known in the vacuum business, yet an innovative filtration system allows all that power to be compressed into a fraction of the system footprint and weight of conventional vacuum trucks. This innovation has also made the process safer and the operation more straightforward, allowing customers to easily operate the equipment without special certifications. Customer personnel can learn to operate the system in less than 10 minutes.

Cost Savings of 40-60%

It is a big idea in a small package, an idea that’s made a big splash in the industrial vacuum industry. Triton systems have replaced the need for expensive and cumbersome industrial vacuum truck operations. In the past, many projects required expensive 18-wheeler rigs and crews of 2 or more licensed and trained third-party personnel to operate, as well as a lot of space for the truck to maneuver. Customers who use Triton system report a cost savings of 40-60% against their total vacuum bill.

Triton Industries has also dedicated ourselves to providing a high level of customer service — offering a combination of quality products, responsive service and innovative product development.

The Kraken

The Kraken

Michael James also invented and patented the Kraken vacuum fed, positive displacement system, which is also named from Greek mythology, and is used in several demanding applications.

2010 – Cleaning Up the Environment

In 2010, Triton Industries received national attention for the role its equipment played in helping clean up the BP Deepwater Horizon oil spill. Triton’s vacuum systems were perfect for placing on shallow water barges due to their lighter weight and smaller size. As a result, Triton received a number of regional and national awards for its efforts.

Companies We Work With

What They Say

For what it’s worth, After several weeks of working with the 1500 Liquid ring, I gotta tell you guys, I absolutely love it. Great design, fool proof, low maintenance, performs brilliantly, a good solid piece of equipment. Simplicity and performance.

Using Triton equipment, we recovered steel shot faster than we ever have, we did it safely, and at a lower cost. I’d recommend anyone consider using Triton equipment.

We felt we had a huge benefit on cost, particularly running our job 24 hours a day. Additionally, the customer service and support from Triton was excellent. We’ll definitely use Triton again.

I work on the North Slope of Alaska offshore on a drilling project with your solids recovery units. They work quite well for us , especially since we use them day in and day out in extreme conditions.